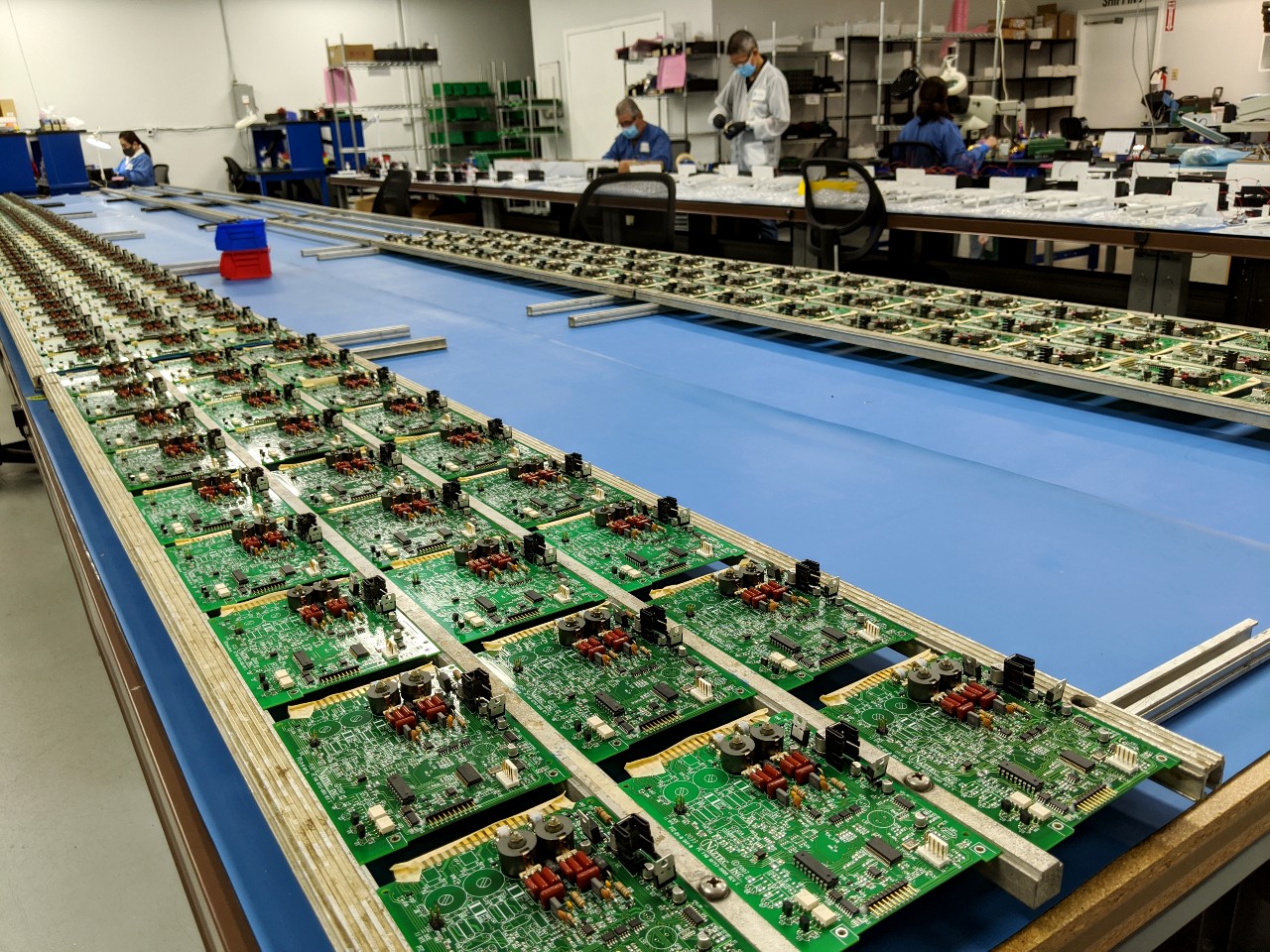

Turnkey, Partial Turnkey, and Labor Only PCB Assembly

Whether we purchase the parts on your bill of materials or you provide parts for assembly (labor only), we are here for you. We are Texas's printed circuit board assembly experts and our customers have trusted our expertise for over 30 years. Contact us today for a free quote. We look forward to hearing from you.Assembly Types

| SMT | Surface Mount Technology |

| TH | Thru-hole Technology |

| Mixed Technology | Both Thru-hole and Surface Mount Technologies |

| Single & Double Sided | Double Sided Surfact Mount and Thru-hole Assembly |

Solder Types

| Sn63 | Eutectic Tin-Lead Solder (63% tin, 37% lead) |

| SAC305 | RoHS Compliant Lead-Free Solder (96.5% tin, 0.5% copper and 3% silver) |

Order Quantities

| No Minimum | We are happy to assemble just 1 prototype board if required. |

| No Maximum | Fully capable of assembling up to 10,000 boards in a single production run. |

Turnaround Times * Subject to Materials Availability

| Labor Only Production | 4 week standard lead time after receipt of materials from customer. | |

| Turnkey Production | 6-8 weeks standard lead total. | |

| Quick Turn Production | 1 and 2 week turnaround available for production volumes. | |

| Prototype | 48 Hour to 2 Week turns available for prototype runs. |

Component Types

| Passives | 01005, 0201 and above. |

| Ball Grid Arrays (BGAs) | Includes 100% X-Ray Inspection |

| Fine Pitch | Down to 8 mil pitch. |

Inspection and Testing

| Automated (AOI) | 3D Automated Optical Inspection, Verification of all SMT components. |

| Visual | Visual Inspection using Mantis Microscopes (12x magnification) |

| X-Ray | For BGAs and Leadless Components |

| Functional Testing | Functional Testing and Programming with your Test Fixtures and Procedures |

Component Packaging Accepted

| Reels | Reels are the most cost effective and dependable packaging for passive components. |

| Tubes & Trays | ICs typically come packaged in Trays or Tubes. |

| Loose Parts | During prototyping loose parts are often unavoidable. We will accept these upon review. |

| Cut Tape | Cut tape is accepted for ICs and passives sized 0603 and larger. |